INTRODUCTION

Man is in direct competition with a variety of other species for food. These competitors not only consume the product but also contaminate the product with feces, exuviae or hairs, frass and microorganisms. They can also alter the physical properties of the product by increasing temperature and possibly moisture content, and pose health threats by acting as vectors of pathogens and parasites. The importance of implementing effective pest management strategies cannot be overemphasized as the discovery of live insect stages or contaminants such as insect fragments and exuviae, or rodent hairs and droppings, has severe financial implications. Such incidents usually lead to the recall of the entire distribution of a particular product and may result in expensive litigation procedures, but potentially the greater financial loss is the longer-term effect on consumer confidence in the product which may never be fully restored. In food production facilities there is a constant threat of pest populations becoming established as food is always present and there are many locations and access points for pests to enter and find refuges. Insect food pests are cosmopolitan while food facilities are twice as likely to encounter rodent problems in comparison with domestic premises and are legally bound to practice high food safety standards (HGCA, 2002). Many procedures can be adopted to prevent pest access, to detect their presence on arrival and to control infestations when they occur, and these are discussed below.

PESTS OF FOOD PROCESSING AND PRODUCTION FACILITIES AND

THE RISKS THEY IMPOSE

Any site where food is gathered, sorted, processed or stored is an attract ion to wandering rodents, birds, insects or mites whose lives depend on the successful location of food sources. Farmers, crop storage and distribution specialists, food processors and retailers all need to take precautions to render their premises less vulnerable to exploitation by pests. While problems from vertebrate pests can largely be addressed by exclusion strategies, the same is not true for insect and mite pests, although exclusion strategies are still an important ingredient of pest management. Incoming supplies are the primary source of these pests and many species can become established in the fabric of the building, feeding on food residues and wandering to and from harborages to locate new supplies.

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

Vertebrate Pests

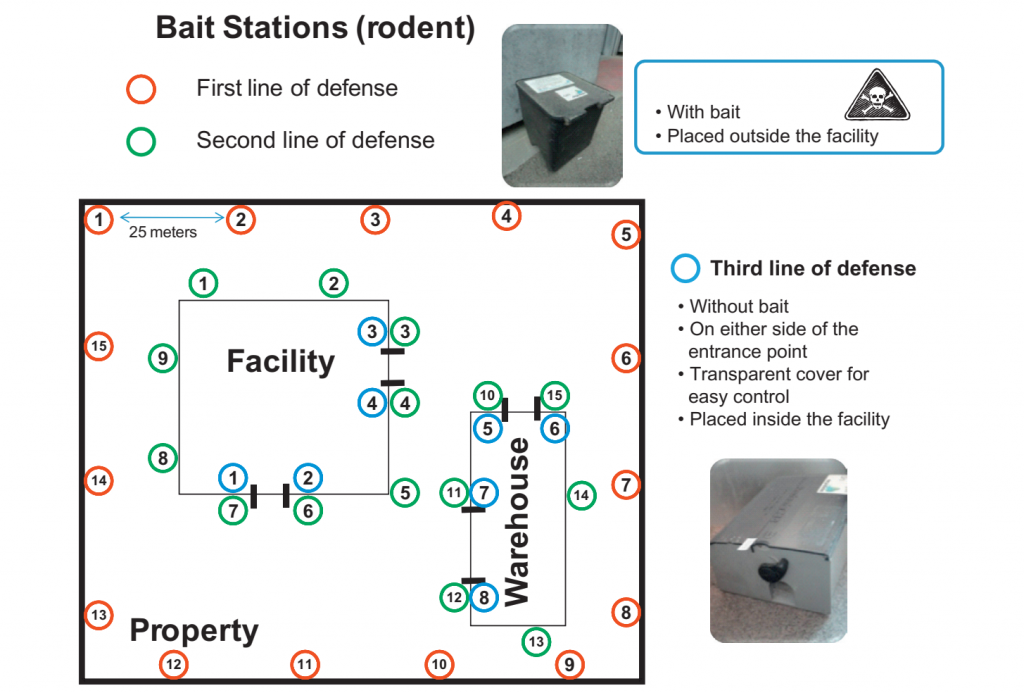

Rats, mice, sparrows and pigeons are ubiquitous and major sources of contamination of food products in food processing facilities. They act as vectors of Salmonella, Shigella and Leptospira bacteria, various viruses, rickettsia causing Q fever and other pathogens. Weil’s disease caused by Leptospirosis icterohaemorrhagiae picked up by contact with rat excreta can be fatal, as can some cases of Salmonella food poisoning. Rodents also cause damage by the gnawing of wood, plastics, electric cabling and even metal water pipes, sometimes with catastrophic consequences. For birds, netting of openings and needle-matting of surfaces are well established, effective strategies to prevent ingress, but problems may still occur where continual access for transport is needed or weathering of buildings provides openings in inaccessible areas of roofing where birds such as sparrows, starlings or pigeons can gain access. Rodent-proofing is a more complex problem as in addition to the obvious exclusion of ground-level entry points, attention needs to be paid to the drainage system as well as roofing eaves as rodents will ascend drainpipes, either internally or externally, and gain access to lofts and then through the whole building via heating ducts or piping and along electrical conduit routes. Access of rats from sewerage systems is also not an uncommon occurrence so screens and other barriers should be in place and regularly maintained. The use of rodenticides for rat control requires the involvement of trained operators and even after careful observance of regulations is still a potential risk to non-target organisms (Eason et al., 2010). Resistance has developed to anticoagulants such as warfarin and now only second generation compounds are in widespread use, difenacoum and bromadiolone for use indoors and outdoors and the more toxic brodifacoum and flocoumafen for indoor use only under carefully controlled conditions. Formulation and mixture with an appropriate food is of critical importance as baits are readily rejected. All baiting stations should be checked weekly and replaced if necessary (HGCA, 2002). Anticoagulants have always been less effective against mice because of avoidance following small intakes of bait, and since the loss of calciferol based on vitamin D3 no really effective bait is available. Physical traps are used to complement anticoagulant baiting strategies along with single dose agents based on alphachloralose or zinc phosphide. In addition sodium cyanide and aluminum phosphide formulations are available for fumigation treatment of rat harborages and burrows away from occupied buildings. However, none of these complementary measures can guarantee adequate control and for each facility an effective exclusion and trapping strategy is therefore a necessity. Externally, access by rodents to buildings is prevented by clearance of all shrubbery and disused machinery from the vicinity of the exterior walls and the deployment of traps at regular intervals around the property and both inside and outside potential points of entry into buildings. A typical layout of trap deployment for a food facility is presented in Figure 1.

FIGURE 1. A typical layout of rodent traps for the protection of a food processing enterprise. By permission of

R. Stadler

Beetle Pests

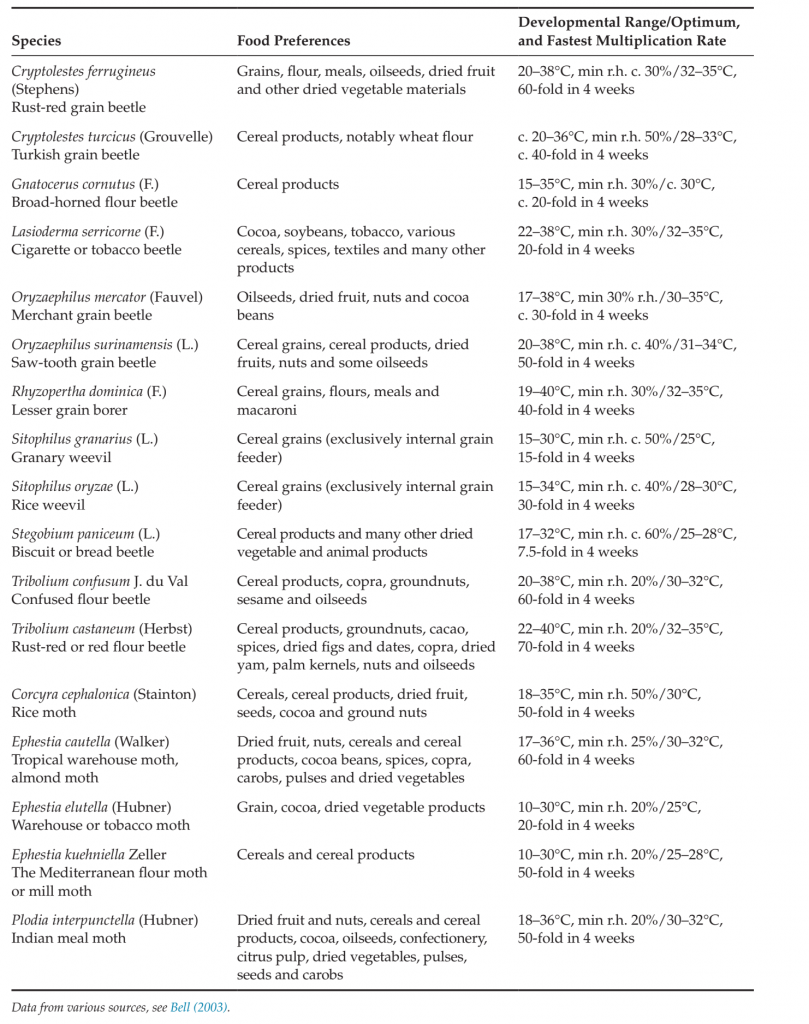

Coleoptera is the largest order of insects and provides the majority of stored product pests with over 20 species of beetle or weevil of worldwide importance in international trade. Table.1 lists some that are commonly associated with food processing facilities, together with their food preferences and requirements for rapid development. Many species are of tropical origin that have arrived and become established in heated premises since the advent of international trade. Others, such as the biscuit beetle and granary weevil, famous for infesting sailors’ biscuits and grain supplies in the days of sailing ships, are native to temperate regions. Excavations of archeological sites have found dead specimens of the biscuit beetle in leather artifacts dating back to Roman times and in the remains of food left in tombs in ancient Egypt.

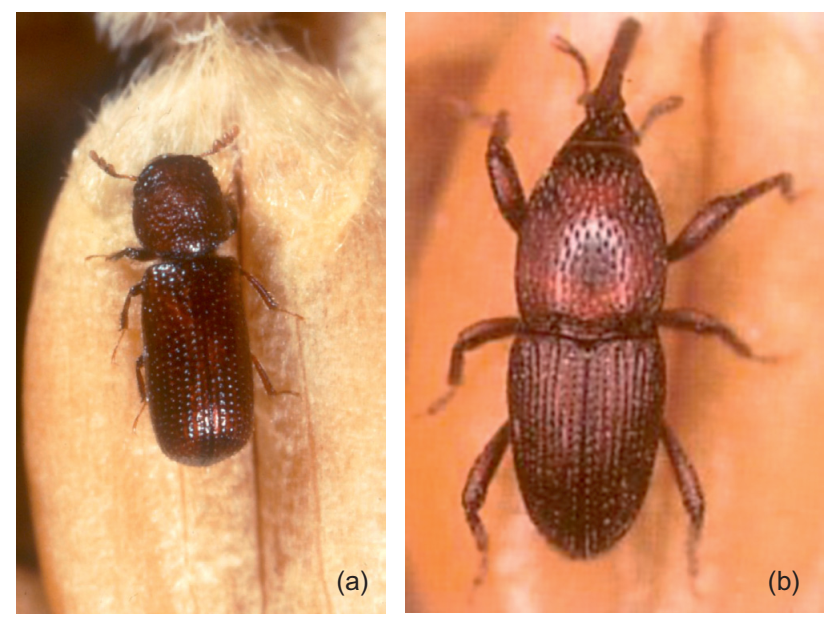

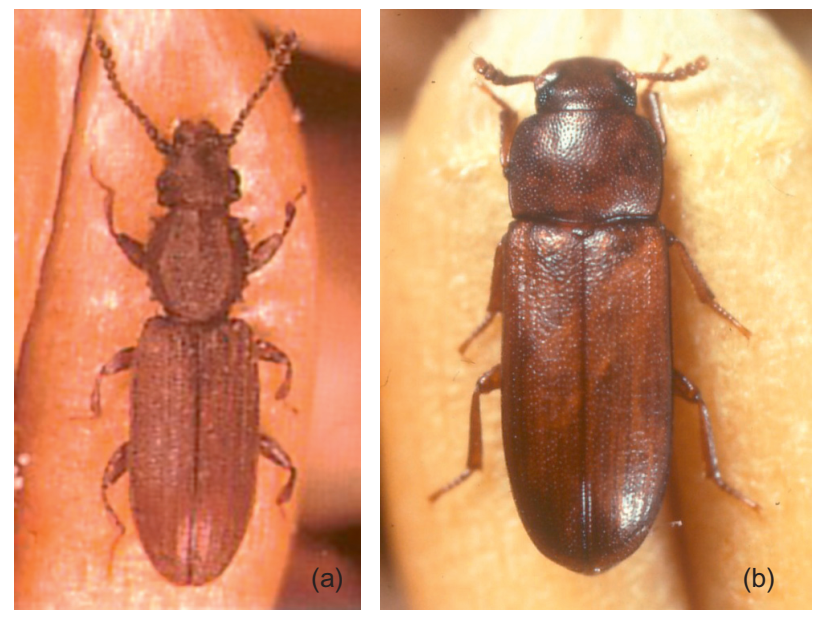

Stored-product beetles may be divided into two categories, those developing externally on semiprocessed foods and among finely divided products, and those internal feeders developing within whole seeds such as cereal grains and legumes. The latter group includes bruchids, weevils (Curculionidae) and grain borers (Bostrichidae) which cause problems because of infested raw materials and rarely become endemic in the structure of the food production facility. They are, however, notoriously difficult to eradicate because they avoid detection and are protected from direct contact with control measures. The lesser grain borer and the granary and rice weevils occur as pests of rice and flour mills in this manner (Figure 2).

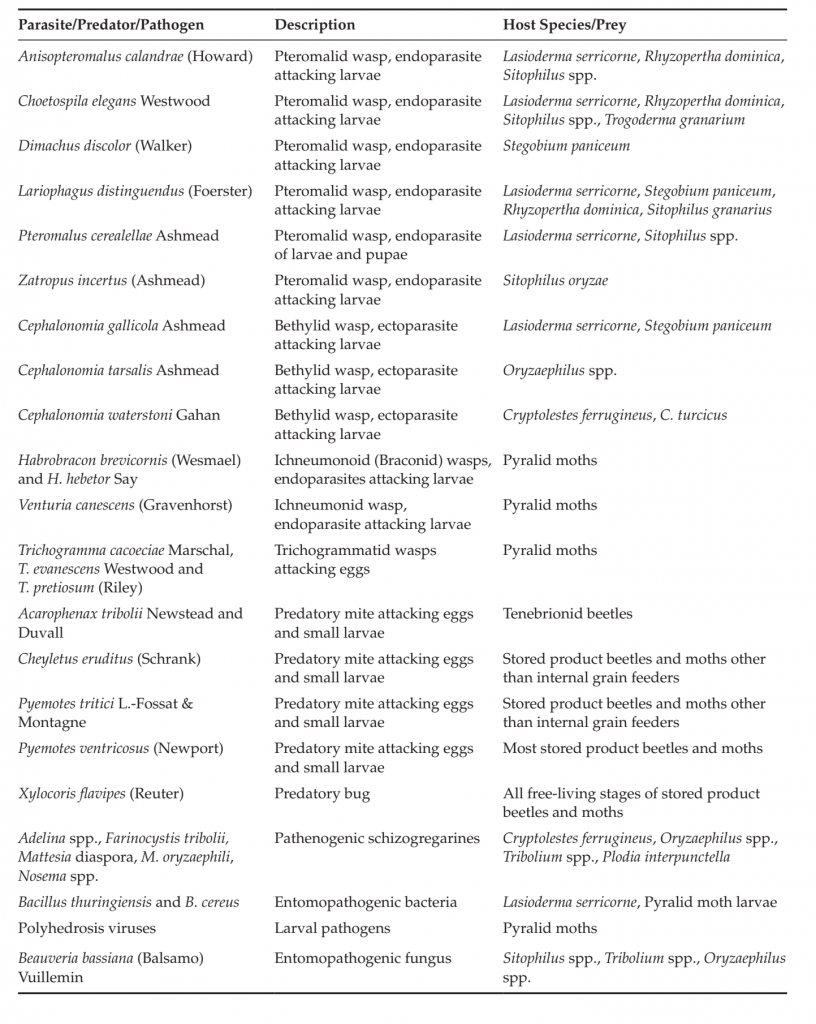

Those beetles feeding on semi processed materials or foods may again be divided into two groups, those with relatively short-lived adults (anobiids such as cigarette beetle, and dermestids such as Khapra beetle) and those whose adult stage may last a year or longer. In this latter group, including the Tribolium and Cryptolestes species which are serious flour mill pests, and the Oryzaephilus (and also Tribolium) species (Figure 3) occurring widely in breakfast cereal, pet food and confectionery manufacturers, both larval and adult stages actively feed on food products. It is this group that often establishes residual infestations in cracks, crevices and voids where food material escaping from processing machinery may accumulate. The long-lived adults seek out harborages from which they wander, often in a daily cycle, to scavenge for food and locate additional oviposition sites from which fresh infestations may start.

FIGURE 2. Two internally feeding grain beetles: A. Lesser grain borer Rhyzopertha dominica; B. Granary

weevil Sitophilus granarius.

TABLE 1 Developmental Requirements of Beetle and Moth Pests Often Found in Food Processing

Facilities

FIGURE 3. Two externally feeding grain beetles: A. Saw-toothed grain beetle Oryzaephilus surinamensis;

B. Rust-red flour beetle Tribolium castaneum.

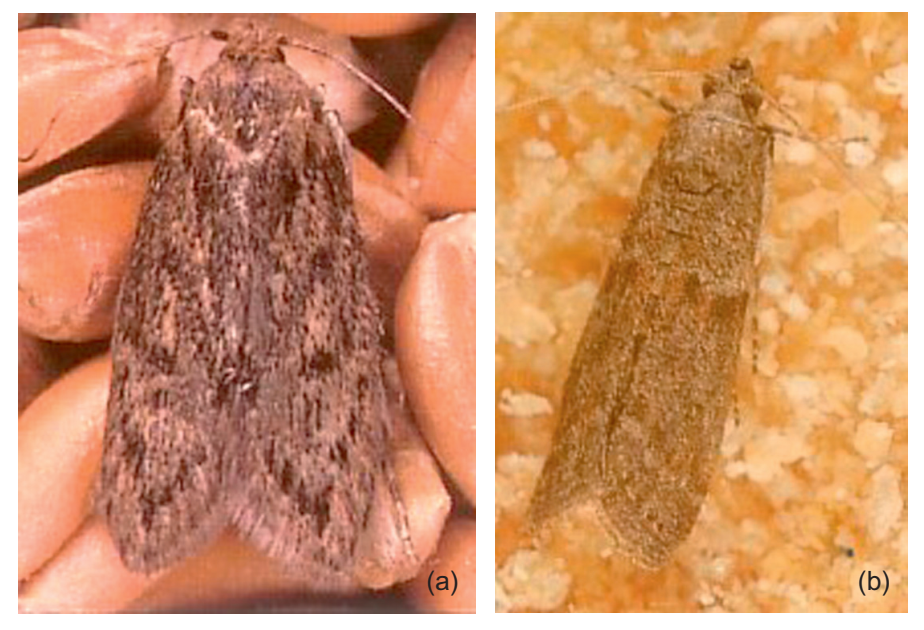

FIGURE 4. Two moth pests of stored products: A. Brown house moth Hofmannophila pseudospretella;

B. Almond moth Ephestia cautella.

Despite their tropical origin and need of warm conditions for breeding, adults of many species of stored product beetle, both “internal” and “external” feeders, are highly cold tolerant and can readily overwinter in parts of the facility. Long-term infestation problems are revealed. if the mealworm Tenebrio molitor L., at 12–17mm in length the largest of all stored product beetles, Gnatocerus spp. flour beetles or spider beetles (Ptinidae) are present in the facility. Moths Most moth pests of food processing facilities belong to the family Pyralidae, although the brown house moth Hofmannophila pseudospretella (Stainton) (Figure 4), and the whiteshouldered house moth Endrosis sarcitrella (L.), are commonly encountered in damper, cooler situations such as mill basements and storage areas (Bell, 2003). Adult moths do not feed and damage is caused by the larval stage which features a heavily sclerotized head capsule with biting and chewing mouthparts while the rest of the elongated body is flexible, unpigmented and unsclerotized. In addition to the consumption and contamination of food, moth larvae produce silk from glands in the mouth which builds into webbing that can obstruct machinery and slow down production lines. Oviposition in pyralid moths occurs from dusk onwards, but is inhibited by light (Bell, 1981). The egg stage lasts a maximum of 7 days at 25°C and there are five larval instars. The duration of the larval stage is influenced by temperature, food source, humidity and whether or not a larval overwintering diapause occurs at the fifth instar. On completing their development, in preparation for pupation or diapause, larvae spin a tough cocoon which may be double-layered. The pupal stage lasts about twice the duration of the egg stage at a particular temperature and adults are short lived, females laying most of their 200–300 eggs within 3 days. The rice moth is a serious pest of mills in hot damp climates but can become established in heated premises anywhere in the world. The tropical warehouse or almond moth Ephestia cautella (Figure 4) is the most frequently intercepted moth pest on food imports into the developed world and a common pest of food processing facilities. The Mediterranean flour moth E. kuehniella is the principal moth pest of flour mills and bakeries in temperate regions of the world while the warehouse moth E. elutella, as its name suggests, is largely confined to warehouse storage areas where it overwinters as a diapausing larva, able to tolerate temperatures down to −10°C. The arrest is triggered by late summer day lengths of less than 14 hours (Strumpel, 1969). The Indianmeal moth Plodia interpunctella, perhaps the most versatile of all the pyralid species in occupying niches in the food industry, can also overwinter as a diapausing larva. Details of the developmental limits and optima for each species are provided in Table 1, together with their food preferences. Other Insects Cockroaches, flies, ants and psocids can also cause problems in food processing facilities. The principal cockroaches belong to the genera Periplaneta, Blatta or Blatella. Eggs are produced in capsules, with up to 40 eggs per egg case and nymphs can mature to adults within 12 weeks. Cockroaches are disease vectors and, particularly Blatella germanica (L.), can cause allergenic problems, besides the obvious risks of contamination and spoilage of food (Ebeling, 1991). Most species are cryptic, hiding in refuges with access to food residues. Many different flies are hygiene threats in industry, including house flies, blow flies, fruit flies and drain flies, each originating from different sources of hygiene failure. They can transmit many fecal and oral-borne pathogens. UV Light traps are widely employed to monitor and control flies in bakeries, restaurants and food processing plants and keep problems under control as long as adequate attention is paid to remove potential breeding sites (Taylor, 2008). Ants have caused problems at most food production or processing premises at some time or other. Worker ants forage for food and carry it back to a central nest often at a considerable distance from the food source, leaving a chemical trail from that source. The result is that increasing numbers of workers appear in the facility, all following the same path (Beatson Campbell, 1991). Two species regularly causing problems in houses, hotels, restaurants, hospitals, warehouses and food production and processing facilities are the common black ant Lasius niger (L.) and the pharaoh’s ant Monomorium pharaonis (L.). The latter can be controlled by insecticide baits based on juvenile hormone activity because, unlike the Lasius spp., there is usually only a single queen producing eggs in the nest. Psocids are tiny, primitive insects feeding mainly on molds and decaying vegetable material in damp situations. They sometimes appear in huge numbers on food materials in commercial or domestic premises. The smallest opening in a food package can provide a point of entry for the minute nymphal stages. The commonest species is Liposcelis bostrychophila Badonnel, a rapid-moving, wingless, pale-colored insect about 1 mm long for which only females are known. Parthenogenetic multiplication can be rapid, but temperatures above 20°C and high humidity are needed for egg production (Turner, 1994).

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

Mites

Mites, more closely related to spiders than insects and extremely small, utilize icroenvironments of moderate temperature and raised humidity. The most important family associated with food storage problems is Acaridae, though the dried fruit mite Carpoglyphus lactis (L.) (Carpoglyphidae) and cosmopolitan food mite Lepidoglyphus destructor (Schrank) (Glycyphagidae) are also common pests. The life cycle includes a brief larval stage typically followed by three nymphal stages prior to the reproductive adult stage. Their rate of increase is unparalleled by any insect, with only 14 days being needed to complete development under optimal conditions and with a single female being able to produce 555–600 eggs (Cunnington, 1965; Boczek, 1991). Eggs are cold tolerant and in some species development can proceed down to 5°C, but in all species low humidities prevent development. The flour mite Acarus siro L. is able to infest any food used by humans if the local environmental conditions are suitable. The mold mite Tyrophagus putrescentiae (Schrank) is perhaps the most cosmopolitan mite pest of stored products, occurring in any product with a high fat or protein content. The tiniest opening permits entry of mites into packaged products and, once inside, an unpleasant taint is produced in the substrate. Many mites are also strongly allergenic.

MINIMIZING PEST OCCURRENCE IN FOOD PREMISES

It can be seen from the optimum requirements of insect pest species that the ideal environment of food processing premises should be one of low temperature, low humidity and an absence of accessible food sources. Unfortunately, none of these parameters can be maintained throughout a site and so there are always tensions in striving for the right balance between production needs and pest avoidance. Most food ingredients are vulnerable to pest attack, especially those with an equilibrium relative humidity above 65%, and the continual movement of commodities to and from trade premises poses a constant threat of importing pests. In nearly every country legislation demands the highest standards for any food product destined for human consumption, so the elimination of pest contamination of food is of paramount importance for the industry. Effective control measures carried out at the source of raw ingredients provide a vital start to the chain that leads to the final processed product. Buildings need to be designed to avoid access points from outside and doors and windows need to be precision fitted and kept closed whenever possible. Recessing of external drainpipes prevents a ready access route to the eaves for rodents and wall surfaces should have a smooth finish both inside and outside. Internally, minimization of voids, ledges, crevices or dead spaces is an important aspect at the planning stage as these provide locations where insect pests can establish refuges. New machinery and facility construction should include pest preventive design as a priority. Rigorous, systematic cleaning of processing machinery and food production areas on a regular basis helps reduce risks of infestations becoming established. Timely and appropriate removal of accumulating waste and debris by vacuum cleaning, sweeping and washing is another vital aspect to be built into management practice. Streamlining product distribution to reduce residence time in store, and avoidance of storage alongside other less secure products, are other goals in the quest to avoid infestation problems. Care should also be taken to avoid stacking products in corners or near to walls, which reduces access for cleaning and creates a harborage for pests. Packaging can be an effective measure for reducing access of pests to food materials after processing but standard carton designs generally provide little protection against stored product insects. The spot weld glue patterns commonly used tend to leave channels through which smaller insect or mite stages can enter and does not provide a complete seal (Mullen and Mowery, 2000). Card, paper and cellophane wrappings are the least resistant to insect penetration, while polycarbonate, some polyesters, polyurethane and aluminum foil are much more resistant (Rao et al., 1972; Cline, 1978; Highland, 1984; Bowditch, 1997; Collins, 2003). All packaging is vulnerable to damage by rodents, and insects such as the lesser grain borer, biscuit beetle, cigarette beetle and larger larvae of pyralid moth species possess powerful biting mouthparts and are also able to penetrate most films. Any measures to improve packaging design by reducing the chance of an incomplete seal, and removing joins, folds and corners that are susceptible to mechanical damage or provide leverage for insect mouthparts, should be implemented. Over-wraps also improve resistance, particularly if applied as shrink-wraps fitting tightly around the package. A higher level of protection is provided by the “form-fill-seal” machines employed in modified atmosphere or vacuum packaging. A heat-molded base tray is filled with product and a flat lid is heat sealed across the top in the relevant atmosphere for the product. All the above measures have economic implications and require there to be an adequate profit margin for the final product. Furthermore, although the presence of pests can be minimized, total elimination of pest incidence can never be guaranteed. There is therefore a need for measures to detect pests at an early stage before they locate and damage the product. Meanwhile research continues to refine methods of excluding and controlling pests (Riudavets et al., 2009; Moerman, 2010), but problems can only be avoided if vigilance is maintained and management procedures are optimized and rigorously applied.

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

PEST DETECTION STRATEGIES

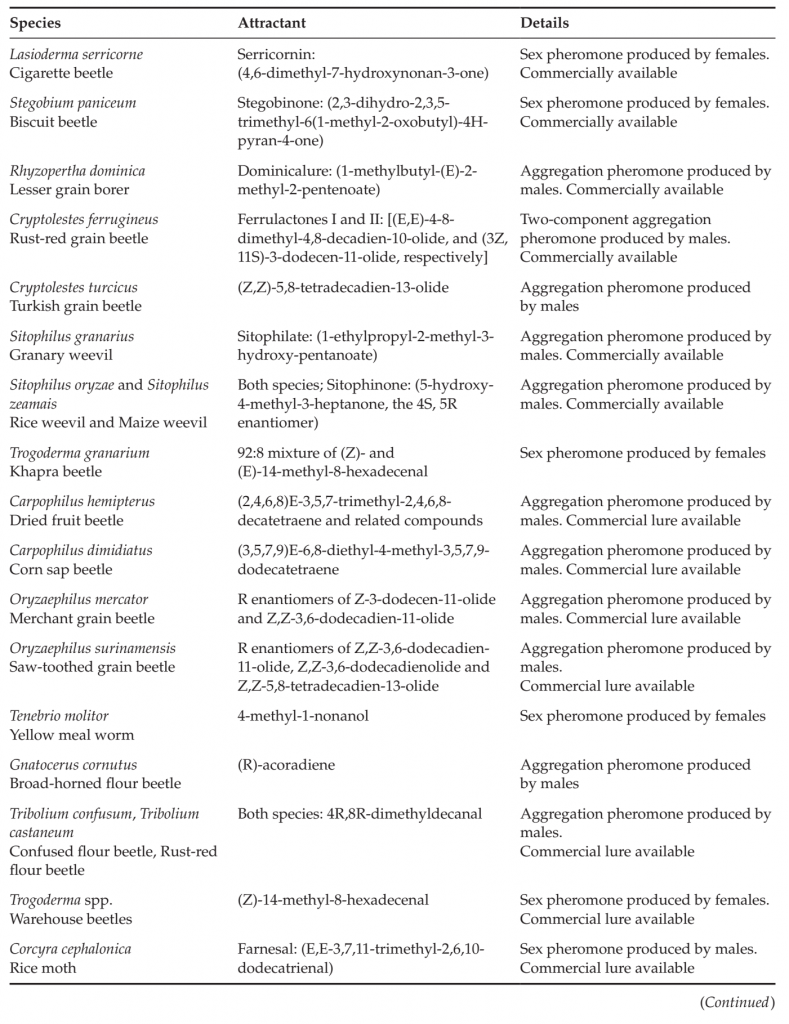

A vital part of pest management programs is the early detection of pests. Many systems of trapping have been employed over the years, ranging from sticky papers and tapes, baited traps of various kind and thin lines of grease or food grade mineral oil around processing machinery or other vulnerable areas. The present focus is on the use of pheromones, the volatile chemicals released by the pest insects themselves that function as a means of communication between individuals (Burkholder and Ma, 1985; Campbell, 2007), and on food volatiles (Collins et al., 2007). Pheromones are particularly important for insect reproduction, both in long-range attraction of the opposite sex and short-range mate location. The chemical structure of pheromones has been analyzed for a large number of species of concern in stored product protection (Burkholder and Ma, 1985; Phillips, 1997). A list of some of the materials that have been isolated and identified is given in Table .2. There are two basic types of pheromones involved in pest detection systems, sex pheromones and aggregation pheromones.

TABLE 2. Attractants Produced by some stored Product Beetles and Moths

TABLE 2. Attractants P

Sex Pheromones

Sex pheromones are usually emitted by females to attract males for mating. They have been reported from many moths and certain families of beetles including Anobiidae, Bruchidae and Dermestidae in which adults are relatively short-lived and feed very little or not at all (Burkholder and Ma, 1985). Sex pheromone activity may be exclusive to a single species but commonly may be shared between several related species. Thus, the sex pheromone TDA (Z, E)-9,12- tetradecadienyl acetate (also known as ZETA), is active not only against Plodia interpunctella but also against at least four other of its pyralid relatives (Brady et al., 1971). Similarly, the anobiids Stegobium paniceum and Anobium punctatum share stegobinone (Kuwahara et al.,1978), and several Trogoderma spp. share (Z)-14-methyl-8-hexadecenal (Cross et al., 1976).

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

Aggregation Pheromones

Aggregation pheromones are usually produced by males and attract both sexes to suitable abitats and food sources where mating can then proceed. Beetles of the families Bostrichidae, ucujidae, Curculionidae and Tenebrionidae which have adults that feed and are relatively long-lived substantially release pheromones of this type. As with the sex pheromones, aggregation pheromones may involve mixtures of materials and related species may share a common pheromone (Table 2). Aggregation pheromones have also been reported from mites (Kuwahara et al., 1982).

Food Volatiles

A wide range of volatiles and aromas emitted from food materials are attractive to stored product insects, notably those from groundnuts and carobs, and even plain water is effective in attracting moth species in dry conditions (Wakefield et al., 2006; Nansen et al., 2009). Food bait traps have been employed widely in food processing facilities to monitor for the presence of beetle pests with varying degrees of success. The combined use of pheromones and food attractants offers the prospect of a monitoring system for a wide range of pest species.

Pheromones as Pest Management Tools for Detection and Monitoring of Pest Populations

Pheromones are powerful attractants because of the extreme sensitivity of insects to these cues, and enable infestations to be detected at very low levels when visual or other forms of inspection are unlikely to be successful. This information is a critical input for pest management programs and associated decision-support systems in the food industry, where contamination, not only by whole insects but by fragments of them, is a major public health issue. Discovery in a laboratory oil flotation test of rodent hairs, mite or insect fragments in a product sample is the retrospective discovery of a control failure, requiring urgent action to locate the source and revise pest management procedures. Pheromones are often complex mixtures of related compounds and their stereo-isomers can evoke vastly different responses in the species concerned; correct identification, synthesis and blending of the components is essential. Efficient delivery mechanisms for pheromones are also crucial. They must be capable of being adjusted to produce the appropriate concentration level for the species concerned, releasing the pheromone at a uniform rate, and have a capacity consistent with the particular application and operational lifetime. Trap design is important for both walking and flying insects. The distribution of traps in the treatment area is also a key factor. A vital issue after detecting the presence of insects in a facility is the accurate location of the infestation origin and to this end, precision targeting of infestation sources by spatial analysis has proved useful (Campbell, 2007; Trematerra et al., 2007), enabling control measures to get under way before other signs are evident.

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

PEST CONTROL STRATEGIES

Chemical Control Methods

Until recently chemicals were the mainstay for pest control in the food and agricultural industry but there has been a steady move away from reliance on biocides as a succession of adverse side effects for one compound or another have come to light. Hence the more toxic substances have largely been replaced and the use of the remaining materials is being confined to application to surfaces or areas where subsequent contact with food or packaging is unlikely, thus avoiding the problem of chemical transfer to the food (Highland et al., 1984).

Insect Growth Regulators

In recent years the focus has been on developing compounds of highly specific action, based on the physiology of the pest. In this area chemicals that act by disrupting insect life cycles have been developed. Insect growth regulators have come into use for the protection of many stored products such as grain (Oberlander et al., 1997). Methoprene, fenoxycarb and hydroprene are commercially available juvenile hormone agonists, which cause the terminal disruption of insect development but have little or no mammalian toxicity. Their use in admixture on grain or on surfaces such as fabrics can confer protection against pests for over a year. A second group of insect growth regulators act by interfering with the molting hormone ecdysone with consequent prevention of normal metamorphosis and these are effective against Lepidoptera. A third group, effective against cockroaches, act by inhibiting the synthesis of chitin which also prevents normal molting of immature stages. Besides the very long life of the compounds, which can be an issue in international trade if residues of any added chemical are detected, another constraint for the use of insect growth regulators has been in integrated pest management programs where economically important bio-control agents may be adversely affected.

Insecticides and Repellents

The use of insecticidal sprays and dusts has been a routine measure for spot treatment of localized infestations and surface application to areas of high risk. Organophosphorus and pyrethroid compounds remain in use for this purpose though registrations on some compounds are lapsing in many countries, restricting the choice available. Much effort is being placed on the search for new insecticidal compounds of botanical origin and some such as azadirachtin from the neem tree have joined with pyrethrins as registered botanical insecticides. A more recent addition, the bacterial metabolite-based product, spinosad (Fang et al., 2002), is also available as a dust formulation. Dichlorvos space sprays have now been replaced by ULV or aerosol treatments of synergized pyrethrins or pyrethroids in food production facilities, sometimes in mixture with an insect growth regulator such as Methoprene (Arthur, 2010), but are only effective against flying insects. The field of insect repellency is one still under investigation, a non-toxic, non-specific insect and mite repellent being the goal.

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

Fumigants

For many years fumigants have been relied upon for the whole site treatment option when infestation problems get out of control. Flour mills and chocolate factories would typically have an annual fumigation by a licensed company to have a fresh start. To be effective the fumigant had to be suitable for rapid and even distribution throughout the treatment area and in order to minimize production downtime it had to be effective against pests within 24 hours. The first fumigant in widespread use for treatment of structures, hydrogen cyanide, was replaced in the 1960s by methyl bromide, which, though less of an acute toxic risk to operators was still a highly toxic compound. It was extremely effective when used in a well-sealed structure, being an excellent penetrant of voids containing food residues and highly toxic to all pests, achieving control within 24 hours. Methyl bromide, listed as an ozone depleting compound under the Montreal Protocol in 1992, was phased out from all but a few specialist uses in non-Article 5 (developed) countries in January 2005. Developing countries can continue using methyl bromide until 2015, beyond which their use also will be confined to a few quarantine-related circumstances (UNEP, 2006). The only other fumigant widely registered at the start of this century was phosphine, which is an excellent fumigant for commodities in store where the longer residence times permit the long exposure periods (up to 3 weeks at 15°C) required for effective control of pests. Best results are obtained by using a double layer of polythene sheets for packaged materials and treatments may only be carried by registered pest control operators who apply the aluminum or magnesium phosphide gas releasing formulations and dispose of the residues remaining at the end of the treatment according to established procedures. Access to the building in which the fumigation is carried out must be restricted and gas monitoring is required during the 24-hour aeration period after un-sheeting to ensure that local atmosphere threshold limit values are not exceeded before releasing the stock for handling. Phosphine is, however, difficult to use in food processing premises because of its corrosive properties against electronic equipment and the long exposure times required, especially at temperatures below 25°C. Although an alternative fumigant, sulfuryl fluoride (trade name Profume), has been registered for use in empty flour mills starting in Switzerland in 2003, in the UK and Italy from 2004, and now in many European countries, Australia, the USA and Canada, concerns over its global warming potential and the significance of fluoride residues have delayed registrations for use on many food materials or in structures where raw or processed food is present. Its use also requires additional heating as insect eggs are tolerant and would otherwise require long exposure times for control (Bell, 2006). With increasing pressures for the safe and effective use of chemicals, any move away from heavy reliance on them is obviously desirable.

Physical Control Methods

There are opportunities and limitations for the use of physical control methods in structures. The use of modified atmosphere (MA) techniques for space treatments, for example, is restricted to specialist chambers because whereas buildings can be sealed sufficiently for fumigation, they cannot be sealed to the much higher standard required for MA applications. Scope for use of sonic, microwave or radiation technologies is also very limited. Nevertheless several physical methods are of value in the controlling of pest outbreaks.

Heat

For the food processing industry the downtime and production loss arising from whole site treatments to combat pest problems has restricted control options to those which act most rapidly and effectively. This was the principal reason for adopting methyl bromide as the mainstay for a reliable annual whole-site treatment strategy. Heating to 47°C or above results in rapid immobilization and death of insect and mite stages within a few hours. Heat is thus one of the few options offering a similar rate of action to chemical fumigation. The principal problem for heat disinfestation, though, is the planning of heating requirements and heat source deployment to obtain a uniform heat profile throughout the structure without causing high localized temperatures which would cause damage to structural or electronic components. The temperature of air from heaters needs to be limited to 65–70°C to avoid activating sprinklers or causing expansion and cracking; and air speeds should not exceed 5m/s to avoid dust explosions. Structural heat treatment involves raising the building temperature to 50–55°C at a rate of 5°C per hour. Sufficient heaters to ensure that 50°C is reached within 6–8 hours are required. Spot heat treatments may also be carried out where a zone of a processing facility or an item of machinery is heated to above 50°C with a forced hot air stream. Much progress has been made using a combination of heating strategies, often in conjunction with the use of inert dusts to treat areas difficult to heat such as voids and cracks, a procedure first tested in Canada and further developed in Europe (Dowdy and Fields, 2002; Bell et al., 2004). Residual infestations in deep-seated harborages in the basement or elsewhere remain a particular problem. It must be remembered that the target temperatures for control must be reached at the point where the insects reside in the structure, a process that may take 24 hours, and that the presence of protective material such as food residues can lower the temperature experienced by the insect (Bartlett et al., 2005).

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

Cold

The intense periods of winter cold have long been used by millers and warehouse keepers in Canada and the northern USA for a “freeze-out” of pests and there is seldom any need for additional control methods in the first few months after treatment. Cold can also be used as a spot treatment by the injection of liquid nitrogen into confined spaces such as wall voids. However, insulation in walls can affect cold distribution, leaving protected warm spots. Also, surfaces can be stained and warping of wooden structural components may occur. Most insects succumb to exposure at temperatures below −10°C within a few days while below 10°C insect reproduction ceases and population levels of most pests slowly decline (Fields, 1992). The stage of development of the pest is a factor in its cold resistance: eggs are more sensitive, and adults or larvae, especially those in diapause, are the coldest tolerant. Nevertheless, adults of most species can survive temperatures around 4°C for many months and so can readily overwinter in buildings in temperate climates. In consequence, cold exposure requires very long holding times to be effective and this is rarely achievable in the production areas of food processing facilities. Nevertheless, the use of designated cold storage areas for incoming ingredients is a widely practiced measure in many industries in spite of the requirement for high capital investment.

Impaction

Many situations in which agricultural products are mechanically conveyed during food processing offer the opportunity for control of insects by shock, abrasion and impaction. The principle was developed over 70 years ago for use in the flour milling industry and impaction machines such as the “Entoleter” became a routine fixture in facilities such as flour mills (Pagani et al., 2006). In the Entoleter, flour falls between two rapidly spinning discs. Centrifugal force pushes the flour to the edges of the discs where it impacts a row of steel pegs mounted on the rims, and is thrown against the outer steel casing before falling into the basal receiving hopper. The material passing through the Entoleter thus encounters two major impactions and this effectively controls all free-living insect stages. Impaction machines can also kill a high percentage of insects such as weevils developing inside cereal kernels (Vincent et al., 2003; Beckett, 2010).

Inert Dusts

Inert dusts cover a wide range of materials including clays, sands, ashes, diatomaceous earths (DE, fossilized remains of diatoms consisting mainly of silica with small amounts of other minerals), silica aerogels and non-silica dusts, such as phosphate and lime. Inert dusts have a long history of use for grain protection (Ebeling, 1971). Their lethal action against pests is caused by dehydration, the cuticular waxes being adsorbed by the desiccant upon prolonged contact. Abrasion of the cuticular joints in mobile stages may also be a contributory factor but recent formulations are being designed to minimize their abrasive properties to protect conveying machinery. Inert dusts are registered in many countries for treatment of grain and pulses against insect pests and for use as sprays applied to the fabric of food premises to minimize residual infestation and migration of pests. They form a useful part of IPM strategies providing an alternative to chemical protectants for pest control (Dowdy and Fields, 2002). Some formulations are accepted as suitable for use on foods certified as “organic” in some countries. DEs are widely used as food and processing additives.

Irradiation

Irradiation from a cobalt-60 source has been used primarily as a bactericide for many years for treatment of some commodities, mainly spices, but also for dried and fresh fruit, potatoes, onions and poultry. It requires proximity to a commercial treatment source to be practical and consumer acceptance has limited its widespread use. The methodologies for use of irradiation include exposure of a commodity by continuous flow through an irradiator or by batch treatment of cartons by pallet load, or indirect methods such as sterile male release for pest population management. A 10-MeV electron beam unit has also been in use for certain applications but the reduced safety concerns are outweighed by the very low penetrability of commodities, restricting the form in which they can be presented for treatment. Sterile male release has given effective control of heavy field infestations of insects but apart from application in certain warehouse situations is not of relevance to the food industry where the avoidance of insect presence is the goal.

Biological Control Methods

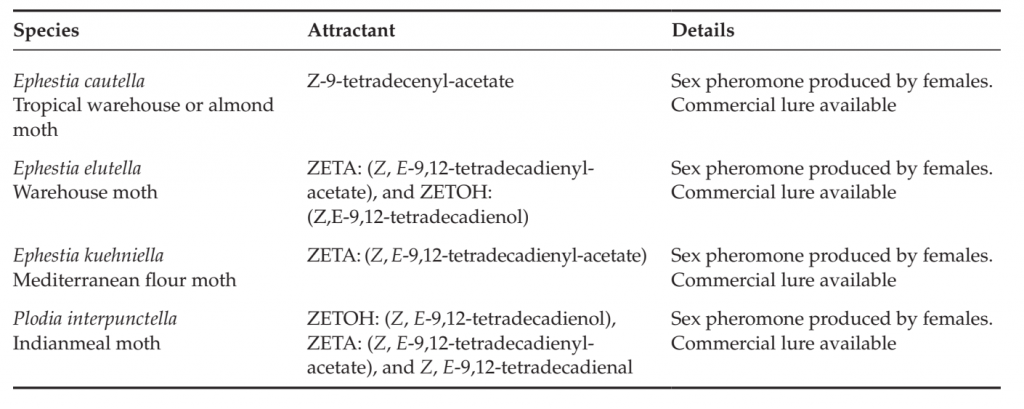

Many organisms are known to attack, infect or parasitize stored product insects, some of which are listed in Table 3. The use of such organisms in food processing facilities is limited by the need to ensure that their presence does not itself lead to problems as discovery of any insect fragments in a finished product is unacceptable. Nevertheless, opportunities exist for their deployment in receival facilities to deal with background pest levels in empty stores as an alternative to cold storage or fabric treatments with insecticides (Scholler et al.,1997). Pathogens are in use in conjunction with attractants to provide a control system for flying pests (Kellen and Hoffmann, 1987), and also as additives to bulk commodities such as cereals (Wakefield et al., 2010).

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

Use of Pheromones for Population Control

Pheromones can be used to provide the attraction agent for mass trapping to physically remove insects, by disrupting mating to prevent breeding, or by acting as an attracticide to a point where pesticides, pathogens or sterilizing agents are used as the control agent. The technique is used to reduce pest populations to manageable levels rather than eliminate them and is most suited to confined areas. It is most effective at relatively low starting population densities. Aggregation pheromones are more effective than sex pheromones because both sexes are attracted to the traps. Nevertheless mass trapping has been successfully trialed with sex pheromones against moths in flour mills to reduce pest populations to a constant low level (Trematerra and Gentile, 2010). The pheromone trap is baited with an insecticide such as cypermethrin or another quick knockdown agent or arrestant to retain the attracted moth. Alternatively, a pathogen source may be incorporated to disseminate disease through the pest population. Another approach is to use sex pheromones to disrupt mating. It is achieved by flooding the environment with the sex pheromone of the target species so that mating behavior is disrupted by false-trail following and sensory fatigue so that mate location and reproduction is minimized. The dispensers need to release adequate amounts of pheromone over a prolonged period and treatments need to be applied before emergence of the target species over a wide area for successful results.

TABLE 3. Potential Biocontrol Agents and their Possible Target Food Pest species

Integrated Pest Management (IPM)

IPM is a pest risk-management approach combining a selection of the methods described above in a way that addresses socioeconomic, health and environmental risks in a sustainable manner while maintaining an acceptable level of productivity. It is highly information based, integrating knowledge about the pests with knowledge about the facility to avoid pest problems and maintain high product quality. A book edited by Heaps (2006) reviews the present status of IPM for mills and processing facilities. For successful implementation, adequate training of industry staff on the tools employed is necessary and this is a problem in some countries where there are few opportunities for formal professional education (Bartosik, 2010). In many cases pest management is contracted out by companies to a registered pest control company with specialist trained staff, but for any management strategy to work the minimum requirement is that a weekly inspection of facilities, and particularly trapping and baiting locations, is carried out and coupled with a clearly laid-out line of action if evidence of pest presence is obtained.

EMERGING THREATS FOR THE SUCCESSFUL MAINTENANCE OF PEST MANAGEMENT

The big issue regarding the continued successful use of chemicals for control of stored product pests is the development of resistance. Pests have become resistant to insecticides, insects growth regulators, fumigants such as phosphine and even to some bacteria-based sprays. The problem is often compounded by cross-resistance to other groups of compounds. Resistance to phosphine was first detected more than 30 years ago and more recently occurrences of strongly resistant strains have been reported from Australia (Nayak et al., 2010) in the rusty flat grain beetle Cryptolestes ferrugineus. To achieve control of this strain at 20°C a concentration of 720 ppm needs to be maintained for 24 days, a far greater dosage than needed to combat previously encountered high resistance levels in the lesser grain borer Rhyzopertha dominica, and other pests. Adoption of alternative strategies that avoid chemical control tends to be costly and labor intensive. This places a burden on the manufacturer that cannot always be passed on to the consumer and can result in lower standards of pest management than when chemicals were in wider use. A related effect that is often overlooked is that the reduced market for chemicals results in products being withdrawn from the market, particularly when an existing compound comes up for regulatory review on a prefixed timetable. Product registration is required in most countries for each chemical intended for use in pest control. Significant efforts have to be undertaken by commercial companies to conduct research, assemble and submit a registration package to obtain a label for legal use of a new compound or to extend the use of one that is under review. The registration process is very costly with lengthy delays and requires that the company developing the product has a high level of technically qualified personnel. Applications are often returned with requests for more data, increasing the expenditure. Where the company can only see a small market in a particular country or application, they are unlikely to proceed with registration. This can result in the disappearance of existing compounds from the market, reducing the options for pest control. Although some problems remain, pest management standards in the food industry have never been higher and research is actively in progress to keep abreast of developments as new pests and new products and procedures come into being.

[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]

References

- Arthur, F.H., 2010. Residual efficacy of aerosols to control Tribolium castaneum and Tribolium confusum. In: Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, Julius Kühn-Archiv 425. Julius Kühn-Institut, Berlin, pp. 788–791.

- Bartlett, D., Conyers, S.T., Bell, C.H., Watson, C.R. , 2005. Further development of heat-based methods for disinfesting flour mills. HGCA Project Report No. 378, Home-Grown Cereals Authority, London.

- Bartosik, R., 2010. Challenges and characteristics of the South American grain and oilseed postharvest system. In: Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, Julius Kühn-Archiv 425. Julius Kühn-Institut, Berlin, pp. 57–62.

- Beatson Campbell, S.H., 1991. Ants: Formicidae, Hymenoptera. In: Gorham, J.R. (Ed.), Ecology and Management of Food Industry Pests. USA Food and Drug Administration Technical Bulletin No. 4, pp. 207–215.

- Beckett, S.J., 2010. Protecting and disinfesting stored products by drying and cooling, and disinfesting stored products during handling by mechanical treatments. In: Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, Julius Kühn-Archiv 425. Julius Kühn-Institut, Berlin, pp. 219–228.

- Bell, C.H., 1981. The influence of light cycle and circadian rhythm on oviposition in five pyralid moth pests of stored products. Physiol. Ent. 6, 231–239.

- Bell, C.H., 2003. Insect pests of stored products in Europe. In: Prakash, A., Rao, J., Jayas, D.S., Allotey, J. (Eds.), Insect Pests of Stored Products: A Global Scenario. AZRA, Cuttack, India, pp. 56–88.

- Bell, C.H., 2006. Factors affecting the efficacy of sulphuryl fluoride as a fumigant. In: Proceedings of the 9th International Working Conference on Stored Product Protection, Campinas, Brazil. Brazilian Post-harvest Association (ABRAPOS), pp. 519–526.

- Bell, C.H., Bartlett, D., Conyers, S.T., Cook, D.A., Savvidou, N., Wontner-Smith, T.J., 2004. Alternatives to methyl bromide for pest control in flour mills. HGCA Project Report No. 329, Home-Grown Cereals Authority, London, pp. 113.

- Boczek, J., 1991. Mite pests in stored food. In: Gorham, J.R. (Ed.), Ecology and Management of Food Industry Pests. USA Food and Drug Administration Technical Bulletin No. 4, pp. 57–79.

- Bowditch, T.G., 1997. Penetration of polyvinyl chloride and polypropylene packaging films by Ephestia cautella (Lepidoptera: Pyralidae) and Plodia interpunctella (Lepidoptera: Pyralidae) larvae, and Tribolium confusum (Coleoptera: Tenebrionidae) adults. J. Econ. Ent. 90, 1028–1031.

- Brady, U.E., Tumlinson III, J.H., Brownlee, R.G., Silverstein, R.M., 1971. Sex pheromone of the almond moth and the Indian meal moth: cis-9, trans-12-tetradecadienyl acetate. Science 171, 801–804.

- Burkholder, W.E., Ma, M., 1985. Pheromones for monitoring and control of stored-product insects. A Rev. Ent. 30, 257–272.

- Campbell, J.F., 2007. Interpretation of pheromone monitoring programs for stored-product insects. Bull OILB/ SROP 30, 57–62.

- Cline, L.D., 1978. Penetration of seven common flexible packaging materials by larvae and adults of eleven species of stored-product insects. J. Econ. Ent. 71, 726–729.

- Collins, D., 2003. Insect infestations in packaged commodities. Int. Pest Control 45, 142–144.

- Collins, L.E., Bryning, G.P., Wakefield, M.E., Chambers, J., Cox, P.D., 2007. Progress towards a multi-species lure: identification of components of food volatiles as attractants for three storage beetles. J. Stored Prod. Res. 43, 53–63.

- Cross, J.H., Byler, R.C., Cassidy Jr., R.F., Silverstein, R.M., Greenblatt, R.E., Burkholder, W.E., et al., 1976. Porapak-Q collection of pheromone components and isolation of (Z)- and (E)-14-methyl-8-hexadecenal, potent sex attracting components, from the frass of four species of Trogoderma (Coleoptera: Dermestidae). J. Chem. Ecol. 2, 457–468.

- Cunnington, A.M., 1965. Physical limits for complete development of the grain mite, Acarus siro L. (Acarina, Acaridae) in relation to its world distribution. J. Appl. Ecol. 2, 295–306.

- Dowdy, A.K., Fields, P.G., 2002. Heat combined with diatomaceous earth to control the confused flour beetle (Coleoptera: Tenebrionidae) in a flour mill. J. Stored Prod. Res. 38, 11–22.

- Eason, C.T., Fagerstone, K.A., Eisemann, J.D., Humphrys, S., O’Hare, J.R., Lapidge, S.J., 2010. A review of existing and potential New World and Australasian vertebrate pesticides with a rationale for linking use patterns to registration requirements. Int. J. Pest Manage. 56, 109–125.

- Ebeling, W., 1971. Sorptive dusts for pest control. A Rev. Ent. 16, 123–158.

- Ebeling, W., 1991. Ecological and behavioural aspects of cockroach management. In: Gorham, J.R. (ed.), Ecology and Management of Food Industry Pests. USA Food and Drug Administration Technical Bulletin No. 4, pp. 85–119.

- Fang, L., Subramanyam, Bh., Arthur, F., 2002. Effectiveness of spinosad on four classes of wheat against five storedproduct insects. J. Econ. Ent. 95, 640–650.

- Fields, P.G., 1992. The control of stored-product insects and mites with extreme temperatures. J. Stored Prod. Res. 28, 89–118.

- Heaps, J.W., 2006. Insect Management for Food Storage and Processing, second ed. AACC International, St. Paul, Minnesota, USA.

- HGCA, 2002. Rodent Control in Agriculture – A Guide. Home-Grown Cereals Authority, Caledonia House, London.

- Highland, H.A., 1984. Insect infestation of packages. In: Baur, F.J. (Ed.), Insect Management for Food Storage and Processing. The American Association of Cereal Chemists Inc., St. Paul, Minnesota, pp. 311–320.

- Kellen, W.R., Hoffmann, D.F., 1987. Laboratory studies on the dissemination of a granulosis virus by healthy adults of the Indian meal moth, Plodia interpunctella (Lepidoptera: Pyralidae). Environ. Ent. 16, 1231–1234.

- Kuwahara, Y., Fukami, H., Howard, R., Ishii, S., Matsummura, F., Burkholder, W.E., 1978. Chemical studies on the Anobiidae: sex pheromone of the drugstore beetle, Stegobium paniceum (L.) (Coleoptera). Tetrahedron 34, 1769–1774.

- Kuwahara, Y., Thi My Yen, L., Tominaga, Y., Matsumoto, K., Wada, Y., 1982. 1,3,5,7, Tetramethyldecyl formate, lardolure: aggregation pheromone of the acarid mite, Lardoglyphus konoi (Sasa et Asanuma). Agric Biol Chem 46, 2283.

- Moerman, F., 2010. Hygienic design of food processing facilities. Food Safety Mag. 16 (5), 50–55.

- Mullen, M.A., Mowery, S.V., 2000. Insect-resistant packaging. Int. Food Hyg. 11, 13–14.

- Nansen, C., Davidson, D., Porter, P., 2009. Using water bottles for trapping of Indianmeal moths in stored peanuts. Ent. Exp. Appl. 133, 251–259.

- Nayak, M., Holloway, J., Pavic, H., Head, M., Reid, R., Patrick, C., 2010. Developing strategies to manage highly phosphine resistant populations of flat grain beetles in large bulk storages in Australia. In: Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, Julius Kühn-Archiv 425. Julius Kühn-Institut, Berlin, pp. 396–401.

- Oberlander, H., Silhacek, D.L., Shaaya, E., Ishaaya, I., 1997. Current status and future perspectives of the use of insect growth regulators for the control of stored product insects. J. Stored Prod. Res. 33,

- Pagani, M., Cravedi, P., Fogliazza, D., 2006. Le macchine ad impatto e il controllo delle infestazioni da Artropodi in cereali e derivati nell’industria molitoria. (Impact machines and arthropod pest management in milling industry, cereals, and cereal products). Tecnica. Molitoria 57, 404–413.

- Phillips, T.W., 1997. Semiochemicals of stored-product insects: research and applications. J. Stored Prod. Res. 33, 17–30.

- Rao, K.M., Jacob, S.A., Mohan, M.S., 1972. Resistance of flexible packaging materials to some important pests of stored products. Indian J. Ent. 34, 94–101.

- Riudavets, J., Castane, C., Alomar, O., Pons, S.J., Gabarra, R., 2009. Modified atmosphere packaging (MAP) as an alternative measure for controlling ten pests that attack processed food products. J. Stored Prod. Res. 45, 91–96.

- Scholler, M., Prozell, S., Al-Kirshi, A.-G., Reichmuth, C., 1997. Towards biological control as a major component of integrated pest management in stored product protection. J. Stored Prod. Res. 33, 81–97.

- Strumpel, H., 1969. Entwicklungzyklen einiger an Rohkakao schadlichen Insekten. Sonderdruck Anz Schadlingsk Pfl Schutz 42, 161–165.

- Taylor, D., 2008. Cleaning up in food facilities. Pest Control Technol. 36 (6), 80–81. 76, 78.

- Trematerra, P., Gentile, P., Brunetti, A., Collins, L.E., Chambers, J., 2007. Spatio-temporal analysis of trap catches of Tribolium confusum du Val in a semolina-mill, with a comparison of male and female distributions. J. Stored Prod. Res. 43, 315–322.

- Trematerra, P., Gentile, P., 2010. Mass trapping of Ephestia kuehniella Zeller in a traditional flour mill. In Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, Julius KühnArchiv 425. Julius Kühn-Institut, Berlin, pp. 745–752.

- Turner, B.D., 1994. Liposcelis bostrichophila (Badonnel) (Psocoptera): a stored food pest in the UK. Int. J. Pest Manage. 40, 179–190.

- UNEP, 2006. Report of the Methyl Bromide Technical Options Committee, 2006 Assessment of Alternatives to Methyl Bromide, United Nations Environment Programme, Nairobi.

- Vincent, C., Hallman, G., Panneton, B., Fleurat-Lessard, F., 2003. Management of agricultural insects with physical control methods. A Rev. Ent. 48, 261–281.

- Wakefield, M.E., Collins, L.E., Bryning, G.P., Chambers, J., Cox, P.D., Fennah, K., et al., 2006. Improved detection and monitoring of beetle pests in stored grain through use of a multi-species lure (LK0929). HGCA Project Report 396, HGCA, London, pp. 81.

- Wakefield, M.E., Moore, D., Luke, B., Taylor, B., Storm, C.G., Collins, D.A., et al. (2010). Progress in the development of a biopesticide for the structural treatment of grain stores. In: Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, Julius Kühn-Archiv 425. Julius KühnInstitut, Berlin, pp. 759–76[ BRSM Certification is accredited for QMS ISO 9001, EMS ISO 14001, OSHMS ISO 45001, FSMS ISO 22000 and QMSMDD ISO 13485 and … ]